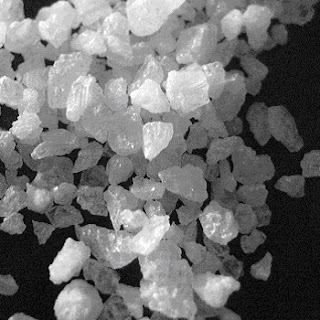

Metal cutting and abrasive surfaces Shuhei process of the main material . In actual production , the commonly used abrasives are synthetic diamond , corundum , silicon carbide, diatomaceous earth, pumice, quartz sand and so on.

Artificial corundum - with high hardness and toughness small ( compared to other abrasives ) is mainly used for rough grinding and polishing low strength metals ( such as pig iron , brass, bronze, etc. ) polished .

Corundum - There are two man-made and natural . The bauxite corundum Al2O3 content , the more the higher the hardness . Corundum is the use of better materials coarse grinding wheel , than artificial corundum toughness . Corundum particles are multi-faceted , sharp edges of particles than artificial corundum was blunt sharp edges . For polishing and tough and has a large breaking strength metals such as hardened steel , malleable iron, manganese bronze.

Emery - with medium hardness and excellent toughness , applicable to all metal polish .

Diatomaceous earth - with less sharp cutting surface and excellent toughness , repairable flat metal surface scratches and scratches and other defects. It is generic , polishing materials .

Quartz sand - particles with medium hardness , it is not a sharp cutting surface , and its toughness is also very good , the universal grinding and polishing materials .

Pumice - its hardness is poor , but also more crunchy , suitable grinding, polishing wood, leather , rubber, plastic and glass.

According to the above kinds of abrasive nature , summed up in the grinding hard metal products , to use artificial corundum , corundum or emery, then fine emery , pumice, finely ground quartz powder . The polished softer metal products , generally with diatomaceous earth and pumice .

Garnet abrasive, island structure is the use of aluminum (calcium) silicate minerals from the processing of ore. Garnet abrasive aka "waterjet sand" or "emery", garnet abrasive having a melting point higher than the major, acid-resistant, wear-resistant, high strength, chemical stability and other characteristics.

2013年9月28日星期六

2013年9月26日星期四

Special diamond polishing technology products and Scope

Now more and more extensive use of polished sand in many areas consistent with the extensive use has been received , so that the scope of these products is very wide, polished sand below introduce you to the basic concepts and polishing abrasives scope .

Polishing sand profile:

High quality silicon carbide abrasive polishing sand as raw materials using modern new unique technology is refined . Abrasive polishing abrasives short time , high efficiency, good benefits , and low prices . The product hardness, high toughness, good self-sharpening , sand consumption is low and can recycle and reuse , grinding pieces of finish is good ; and chemical stability , wear resistance, acid and alkali. The abrasive shell-shaped fracture , sharp corners , constantly smashing step in the formation of new edges and the side edge , making it superior to other abrasive grinding capacity . In particular it has a high hardness, specific gravity , chemical stability and its unique advantages to become self-sharpening , polishing process with abrasive sand is preferred ; while the workpiece is polished rust cleaning , polishing the ideal material.

Polishing abrasives Scope:

Mainly used in the stainless steel surface decontamination, in addition to welding slag and matte effect , iron workpiece to rust, decontamination , descaling , increasing the coating , the coating adhesion, aluminum workpiece descaling, surface hardening , light decoration role of oxidized copper workpiece to Pia light effects , frosted glass crystal , engraved pattern , plastic products ( hardwood products ) matte effect , denim and other special fabrics , plush processing and effect patterns, according to user technical process conditions according to user requirements , customized for the user a variety of polishing abrasives such as sand with emery ; automobile factories, shipyards rust surface polishing with a polishing sand.

Polishing sand profile:

High quality silicon carbide abrasive polishing sand as raw materials using modern new unique technology is refined . Abrasive polishing abrasives short time , high efficiency, good benefits , and low prices . The product hardness, high toughness, good self-sharpening , sand consumption is low and can recycle and reuse , grinding pieces of finish is good ; and chemical stability , wear resistance, acid and alkali. The abrasive shell-shaped fracture , sharp corners , constantly smashing step in the formation of new edges and the side edge , making it superior to other abrasive grinding capacity . In particular it has a high hardness, specific gravity , chemical stability and its unique advantages to become self-sharpening , polishing process with abrasive sand is preferred ; while the workpiece is polished rust cleaning , polishing the ideal material.

Polishing abrasives Scope:

Mainly used in the stainless steel surface decontamination, in addition to welding slag and matte effect , iron workpiece to rust, decontamination , descaling , increasing the coating , the coating adhesion, aluminum workpiece descaling, surface hardening , light decoration role of oxidized copper workpiece to Pia light effects , frosted glass crystal , engraved pattern , plastic products ( hardwood products ) matte effect , denim and other special fabrics , plush processing and effect patterns, according to user technical process conditions according to user requirements , customized for the user a variety of polishing abrasives such as sand with emery ; automobile factories, shipyards rust surface polishing with a polishing sand.

2013年9月22日星期日

Black silicon carbide, and advantages of the use of performance

black silicon

carbide is a very hard material intensity, the product mainly by petroleum coke, quartz sand and silica materials such as smelting, and is widely used in sandblasting, grinding and polishing, carborundum wearable Floor, Carborundum

Abrasives, precision casting mold shell production.

Black Silicon Carbide Uses:

1, the mold surface of the grain,

2, very clean hard surfaces such as: tungsten carbide workpiece

3, with a large sand sculpture in depth, such as stone carving, etc.

4, thin and brittle workpiece sandblasting, cutting

Black silicon carbide Performance and advantages:

Black silicon carbide with anti-crushing ability, corrosion resistance, low cost, high temperature oxidation resistance, hardness, toughness, fitness and other characteristics.

Black silicon carbide is suitable for dry and wet two sandblasting abrasive most affordable, especially for the more rough surface for processing, while the treated surface also requested finer occasions.

Black Silicon Carbide Uses:

1, the mold surface of the grain,

2, very clean hard surfaces such as: tungsten carbide workpiece

3, with a large sand sculpture in depth, such as stone carving, etc.

4, thin and brittle workpiece sandblasting, cutting

Black silicon carbide Performance and advantages:

Black silicon carbide with anti-crushing ability, corrosion resistance, low cost, high temperature oxidation resistance, hardness, toughness, fitness and other characteristics.

Black silicon carbide is suitable for dry and wet two sandblasting abrasive most affordable, especially for the more rough surface for processing, while the treated surface also requested finer occasions.

2013年9月18日星期三

Corundum content of impurities on the properties of

Corundum abrasives in one of many, was able to buy the product is very good, as long as it is attributed to good performance of the product, so that customers are able to favor such a product, but sometimes also corundum There will be miserable impurities, thus affecting its performance.

There are two ways of making corundum, most notably through the method of production of fused corundum, the production process is such high quality bauxite, no trouble coal, iron as the main raw material, through the use of electric arc furnaces in 2200 ℃ above high temperature purification, cleaning, crystallization, sorting, crushing, magnetic separation, screening and other means of processing into various particle size of the product.

The role of corundum quality will affect its effect, how to judge the quality of corundum or bad yet. Corundum in the production process may contain impurities, the main impurities are SiO2, Fe2O3, TiO2, fewer impurities, the higher the quality corundum. Determine the content of impurities in corundum corundum be judged good or bad a way. Besides the content of Al2O3 corundum is also directly explain how good or bad the quality corundum.

Recent years due to rising prices, electricity prices increase the production of corundum increasing pressure, fierce competition in the market there are so many unscrupulous businessmen led to the production of corundum quality is getting worse. Corundum as a wear-resistant materials in recent years, product quality often unstable, chalking, cracking phenomenon of frequent occurrence. So in the purchase process corundum determine its quality is very important.

Corundum can be used as refractory if containing impurities will affect its fire-resistant properties. Some refractories fusible material impurities, and some have a very high melting point in itself, but coexist with the main component, they can produce a fusible material. Therefore, the presence of impurities is often the main ingredient from strong fluxing action. Fluxing action, although the material is liquid phase sintering help, but there is material to resist high temperature serious harm.

There are two ways of making corundum, most notably through the method of production of fused corundum, the production process is such high quality bauxite, no trouble coal, iron as the main raw material, through the use of electric arc furnaces in 2200 ℃ above high temperature purification, cleaning, crystallization, sorting, crushing, magnetic separation, screening and other means of processing into various particle size of the product.

The role of corundum quality will affect its effect, how to judge the quality of corundum or bad yet. Corundum in the production process may contain impurities, the main impurities are SiO2, Fe2O3, TiO2, fewer impurities, the higher the quality corundum. Determine the content of impurities in corundum corundum be judged good or bad a way. Besides the content of Al2O3 corundum is also directly explain how good or bad the quality corundum.

Recent years due to rising prices, electricity prices increase the production of corundum increasing pressure, fierce competition in the market there are so many unscrupulous businessmen led to the production of corundum quality is getting worse. Corundum as a wear-resistant materials in recent years, product quality often unstable, chalking, cracking phenomenon of frequent occurrence. So in the purchase process corundum determine its quality is very important.

Corundum can be used as refractory if containing impurities will affect its fire-resistant properties. Some refractories fusible material impurities, and some have a very high melting point in itself, but coexist with the main component, they can produce a fusible material. Therefore, the presence of impurities is often the main ingredient from strong fluxing action. Fluxing action, although the material is liquid phase sintering help, but there is material to resist high temperature serious harm.

2013年9月16日星期一

Describes how to strengthen corundum production environment

Brown Corundum in the production process have a good production environment , so that we can produce a good product, following a brief look at strengthening the production environment corundum What?

Conventional aluminum oxide abrasive machining process of exercise and ordinary have dust pollution, water pollution, air pollution and noise pollution, echoing national calls , protect the environment, the current management of these enterprises has begun to pollute . Dust Disposal : You can use active anti- pulse bag and cartridge filter to dispose of machining processes occurring dust pollution of the environment . This method is still present the best selection of the dust disposal .Water Pollution Treatment: Alignment washing Alumina Abrasive water pollution , we first use of zero-emission to dispose of the water cycle ; pickling abrasive water pollution , we deal with a high temperature to replace after pickling pickling process completely dispose of water pollution , after a multi- purified water , cleaning water can be seen , the water, the precipitate is filtered in the sewage tank .

2013年9月12日星期四

Do you know the role of powder characteristics is

White fused alumina powder as raw material, made of high-temperature melting. White, slightly higher hardness than corundum, lower toughness. With its manufacture of abrasive for high carbon steel, high speed steel and hardened steel grinding. Used as a polishing material, but also for precision sand casting, coating materials, chemical catalyst carrier, precision wear characteristics.

Green silicon carbide with quartz sand and petroleum coke as raw materials, high temperature melting, green translucent crystals, high hardness, cutting ability, suitable for machining hard and brittle materials, such as cemented carbide, high speed steel, and optical glass, ceramics, agate and other non-metallic heating elements, heat originals.

Green silicon carbide with quartz sand and petroleum coke as raw materials, high temperature melting, green translucent crystals, high hardness, cutting ability, suitable for machining hard and brittle materials, such as cemented carbide, high speed steel, and optical glass, ceramics, agate and other non-metallic heating elements, heat originals.

2013年9月11日星期三

What is processing corundum

Corundum is generally polygonal shape diamond , so the colors are white , then in today's society, many people do not know what is corundum , but do not know what effect it has , generally used in the wrong ?

Corundum Scope:

Etching processing: jade, crystal , agate, semi-precious stones , stamps, ornamental stones , antiques, marble gravestone, ceramic, wood , bamboo , etc. etched art .

Pretreatment processing: PTFE (TEFLON), PU, ??rubber, plastic coated , rubber drum (ROLLER), electroplating, metal spray , titanium , etc. Before treatment, the increase in surface adhesion .

Beautification processing: various gold , K gold jewelry, precious metal or of extinction matte , crystal , glass, corrugated , acrylic, and other non-metallic matte processing and enables the workpiece surface into a metallic luster.

Surface processing: metal oxide layer, carbide black , metallic or non-metallic surface dirt rust removal , such as gravity die casting, rubber mold of the oxide or remove agents from the shape , ceramic surface black spots , uranium -color removal , painting rebirth.

Flash processing: bakelite , plastic, zinc, Alumina Refractory,aluminum die-casting products , electronic parts , core , etc. burr removal .

Stress relief processing: aerospace, defense, precision industrial Parts , rust, paint extinction , renovation etc. stress relieving processing.

Corundum Scope:

Etching processing: jade, crystal , agate, semi-precious stones , stamps, ornamental stones , antiques, marble gravestone, ceramic, wood , bamboo , etc. etched art .

Pretreatment processing: PTFE (TEFLON), PU, ??rubber, plastic coated , rubber drum (ROLLER), electroplating, metal spray , titanium , etc. Before treatment, the increase in surface adhesion .

Beautification processing: various gold , K gold jewelry, precious metal or of extinction matte , crystal , glass, corrugated , acrylic, and other non-metallic matte processing and enables the workpiece surface into a metallic luster.

Surface processing: metal oxide layer, carbide black , metallic or non-metallic surface dirt rust removal , such as gravity die casting, rubber mold of the oxide or remove agents from the shape , ceramic surface black spots , uranium -color removal , painting rebirth.

Flash processing: bakelite , plastic, zinc, Alumina Refractory,aluminum die-casting products , electronic parts , core , etc. burr removal .

Stress relief processing: aerospace, defense, precision industrial Parts , rust, paint extinction , renovation etc. stress relieving processing.

2013年9月9日星期一

Common types of abrasive

Need to use the mold with abrasive, abrasive and share with everyone today, the main species, which mainly include mainly corundum, white corundum, silicon carbide and green silicon carbide.

Corundum high toughness, suitable for grinding carbon steel, alloy steel, malleable iron and hard bronze high tensile strength of the material. Corundum has a higher hardness than corundum, cutting performance is better, for hardened steel, high carbon steel, high speed tool materials such as grinding processes.

Black silicon carbide, high hardness, brittle and sharp, suitable for grinding, cutting, low tensile strength of the material, such as: cast iron, glass, ceramics, stone, refractory material and so on.

Darker green silicon carbide high purity silicon silicide. Suitable for grinding carbide, optical glass, precious stones, agate and other hard and brittle materials.

Granularity:

The choice of abrasive particle size depends on the surface of the workpiece machining accuracy and productivity requirements. Coarse-grained and medium-grained abrasive for roughing and semi-finishing, and fine-grained abrasive, it applies to finishing and super finishing. Physical and mechanical properties are grinding department also factors that determine particle size, low hardness, ductility and toughness of the material is appropriate to coarse-grained abrasive machining, high hardness brittle materials appropriate to fine-grained abrasive.

Organization:

Organization refers to the abrasive grinding composition of the abrasive, bond and porosity volume ratio between the three. Less abrasive, large porosity called loose tissue, otherwise tightly organized.

Tightly organized abrasive, should be used for grinding, profile grinding and processing remain small while the surface finish of the workpiece.

Medium organizations are widely used in the general allowance abrasive grinding work piece.

Loose abrasive for flat organization, such as the inner circle of a large contact surface of the grinding and grinding expansion sensitive soft material of the workpiece and the workpiece.

Hardness:

Abrasive abrasive surface is fixed to the strength of the binding agent. Or under external force, the degree of difficulty shedding, known abrasive hardness.

Corundum high toughness, suitable for grinding carbon steel, alloy steel, malleable iron and hard bronze high tensile strength of the material. Corundum has a higher hardness than corundum, cutting performance is better, for hardened steel, high carbon steel, high speed tool materials such as grinding processes.

Black silicon carbide, high hardness, brittle and sharp, suitable for grinding, cutting, low tensile strength of the material, such as: cast iron, glass, ceramics, stone, refractory material and so on.

Darker green silicon carbide high purity silicon silicide. Suitable for grinding carbide, optical glass, precious stones, agate and other hard and brittle materials.

Granularity:

The choice of abrasive particle size depends on the surface of the workpiece machining accuracy and productivity requirements. Coarse-grained and medium-grained abrasive for roughing and semi-finishing, and fine-grained abrasive, it applies to finishing and super finishing. Physical and mechanical properties are grinding department also factors that determine particle size, low hardness, ductility and toughness of the material is appropriate to coarse-grained abrasive machining, high hardness brittle materials appropriate to fine-grained abrasive.

Organization:

Organization refers to the abrasive grinding composition of the abrasive, bond and porosity volume ratio between the three. Less abrasive, large porosity called loose tissue, otherwise tightly organized.

Tightly organized abrasive, should be used for grinding, profile grinding and processing remain small while the surface finish of the workpiece.

Medium organizations are widely used in the general allowance abrasive grinding work piece.

Loose abrasive for flat organization, such as the inner circle of a large contact surface of the grinding and grinding expansion sensitive soft material of the workpiece and the workpiece.

Hardness:

Abrasive abrasive surface is fixed to the strength of the binding agent. Or under external force, the degree of difficulty shedding, known abrasive hardness.

2013年9月7日星期六

Calcined corundum abrasives advantages

1, the elimination of the aluminum oxide abrasive abnormal expansion: As in the smelting process of fused alumina abrasive containing low-cost titanium (Ti 0, TiO) and titanium carbide, titanium nitride (Tic, TiN), their 1000% to 900% of a calcined in an oxidizing atmosphere, it will further oxidation, the volume increases accordingly, the volume change of the abrasive itself beyond its normal expansion, the expansion is abnormal.

Abnormal expansion of the abrasive, the ceramic corundum grinding wheel causes the firing, the surface mesh cracks, resulting in a large waste, and the use of calcined aluminum oxide abrasive to eliminate anomalous expansion of the most effective means.

2, to improve the toughness of the aluminum oxide abrasive and grinding performance: The study found, this is due to the abrasive in the calcination process, the first corundum crystalline solid melting at the TI3 + is oxidized and cause contraction of the lattice, thereby increasing the abrasive resistance compressive strength, followed by calcination in the granulation process will make the internal stress caused.

Thus, after calcination produces a variety of abrasive grinding tools, not only durable and sharp increases abrasive grinding performance.

Abnormal expansion of the abrasive, the ceramic corundum grinding wheel causes the firing, the surface mesh cracks, resulting in a large waste, and the use of calcined aluminum oxide abrasive to eliminate anomalous expansion of the most effective means.

2, to improve the toughness of the aluminum oxide abrasive and grinding performance: The study found, this is due to the abrasive in the calcination process, the first corundum crystalline solid melting at the TI3 + is oxidized and cause contraction of the lattice, thereby increasing the abrasive resistance compressive strength, followed by calcination in the granulation process will make the internal stress caused.

Thus, after calcination produces a variety of abrasive grinding tools, not only durable and sharp increases abrasive grinding performance.

2013年9月6日星期五

Quartz powder production technology introduced

According to the final use of the product needs to determine the appropriate and suitable purity quartz particulate material , you can make quartz powder ( silica ) grinding .

Basically, the abrasive quartz powder, a wet and dry in two ways , namely wet blended with a certain proportion of the raw materials in water ( if the product is of high purity , deionized water can be used ) , in a grinding machine , then use the water classification ( sub granularity ) , drying process .

This method had previously been used as a wider range of silica processing methods , but because of its need to consume a lot of water , emit large quantities of contaminated water and waste a lot of heat drying , water classification accuracy is relatively low granularity , use is also dwindling .

Currently, only a small part of the requirements of the electronics industry requires a special use of such products.

Dry grinding currently used more widely , and there is more and more increasing trend . The basic approach is to choose a suitable grinding media for grinding and sieving or air classification granularity ( sub granularity ) . In this way , environmental economy , and the exact size air classification , the only shortcoming is that the composition of the wear of grinding media , the product will be a small increase in its ingredients. So choose a highly efficient grinding effect , low wear and, as a small amount of impurities contained in the product acceptable for most industries grinding media are particularly important .

Currently, a large industry proved corundum alumina ( main component of 95% Al2O3, other minor components mainly SiO2) is the most suitable grinding media . Various industries, basically acceptable use of alumina corundum abrasive silica products.

Silicon micro- grinding equipment selection , there are a variety of grinding equipment, a rod mill , cone mill, Raymond machine, but because of its inevitably bring products in the processing of a large number of Fe2O3 content , it can only for the production of building materials, refractory and other industries low demand quartz powder .

Electronics, chemicals , paint and other industries generally use the ball mill, jet mill , but it can be a huge airflow wear suitable only for 2500 mesh products with fine , so far the most widely used is the ball . May be wet , but also for dry -type , for the continuous production , but also for the production batches . Wherein the abrasive media can also choose to select the previously mentioned alumina corundum, quartz can also choose to block itself can also be used with both .

It can also be controlled with air classifier granularity control the final product , is currently the most widely used in the production of silica as a reasonable solution .

Basically, the abrasive quartz powder, a wet and dry in two ways , namely wet blended with a certain proportion of the raw materials in water ( if the product is of high purity , deionized water can be used ) , in a grinding machine , then use the water classification ( sub granularity ) , drying process .

This method had previously been used as a wider range of silica processing methods , but because of its need to consume a lot of water , emit large quantities of contaminated water and waste a lot of heat drying , water classification accuracy is relatively low granularity , use is also dwindling .

Currently, only a small part of the requirements of the electronics industry requires a special use of such products.

Dry grinding currently used more widely , and there is more and more increasing trend . The basic approach is to choose a suitable grinding media for grinding and sieving or air classification granularity ( sub granularity ) . In this way , environmental economy , and the exact size air classification , the only shortcoming is that the composition of the wear of grinding media , the product will be a small increase in its ingredients. So choose a highly efficient grinding effect , low wear and, as a small amount of impurities contained in the product acceptable for most industries grinding media are particularly important .

Currently, a large industry proved corundum alumina ( main component of 95% Al2O3, other minor components mainly SiO2) is the most suitable grinding media . Various industries, basically acceptable use of alumina corundum abrasive silica products.

Silicon micro- grinding equipment selection , there are a variety of grinding equipment, a rod mill , cone mill, Raymond machine, but because of its inevitably bring products in the processing of a large number of Fe2O3 content , it can only for the production of building materials, refractory and other industries low demand quartz powder .

Electronics, chemicals , paint and other industries generally use the ball mill, jet mill , but it can be a huge airflow wear suitable only for 2500 mesh products with fine , so far the most widely used is the ball . May be wet , but also for dry -type , for the continuous production , but also for the production batches . Wherein the abrasive media can also choose to select the previously mentioned alumina corundum, quartz can also choose to block itself can also be used with both .

It can also be controlled with air classifier granularity control the final product , is currently the most widely used in the production of silica as a reasonable solution .

2013年9月4日星期三

The main function of corundum

(1) Due to high temperature, corrosion resistance, high strength and other properties, it poured with steel sliding gate, smelting rare metals, special alloys, ceramics, blast furnace lining (walls and tubes); chemical containers, spark plugs, thermal oxidation resistant coating.

(2) Because of hardness, wear resistance, high strength characteristics, in chemical systems, used a variety of responses utensils and pipes, chemical pump parts; doing mechanical parts, various molds, such as wire drawing dies, extrusion die nozzle pencil, etc.; make tools, dies abrasive, bulletproof material, human joints, sealing ring mold.

(3) corundum insulation materials, such as lightweight corundum bricks, corundum hollow spheres and fiber products, widely used in various high-temperature kiln furnace wall and roof, both high temperature insulation. Size sand corundum corundum block by artificial selection, using the roll, milling, processing Barmac other equipment, particle size by the F8-F325. Mainly used for polishing, grinding, industrial grinding, etc., can also according to customer requirements for washing, pickling and other processing methods to meet the different needs of customers.

(2) Because of hardness, wear resistance, high strength characteristics, in chemical systems, used a variety of responses utensils and pipes, chemical pump parts; doing mechanical parts, various molds, such as wire drawing dies, extrusion die nozzle pencil, etc.; make tools, dies abrasive, bulletproof material, human joints, sealing ring mold.

(3) corundum insulation materials, such as lightweight corundum bricks, corundum hollow spheres and fiber products, widely used in various high-temperature kiln furnace wall and roof, both high temperature insulation. Size sand corundum corundum block by artificial selection, using the roll, milling, processing Barmac other equipment, particle size by the F8-F325. Mainly used for polishing, grinding, industrial grinding, etc., can also according to customer requirements for washing, pickling and other processing methods to meet the different needs of customers.

订阅:

博文 (Atom)