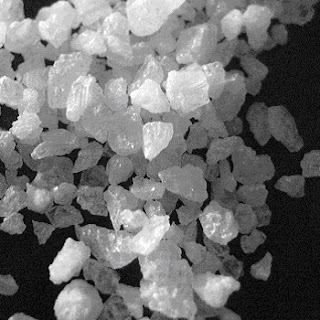

Bauxite (aluminous soil; bauxite), also known as alumina or bauxite, main ingredients are aluminum oxide, hydrate alumina containing impurities, is an earthy mineral. White or grey, brown yellow or light red by iron. From 4 to 3.9 g/cm3 density, hardness, H&X silicon carbide abrasive powder, opaque, very brittle. Very difficult to melt. Insoluble in water, soluble in sulfuric acid, sodium hydroxide solution. Mainly used for aluminium, refractory material.

Main ingredients

The scientific name bauxite bauxite, bauxite. Its composition is extremely complex, a variety of geological sources vary the floorboard of the hydrous alumina ore. As water soft LvShi, hard LvShi monohydrate and sanshui LvShi (Al2O3 · 3 h2o); Have a plenty of diaspore and kaolinite (2 sio2, Al2O3, 2 h2o) company; Some is given H&X Alumina Oxide to with kaolinite, and with higher content of kaolinite, the form for general bauxite or kaolinite clay. Bauxite is generally formed by the chemical weathering or exogenous, there are few pure mineral, mineral always contains some impurities, more or less contain clay minerals, iron ore, titanium minerals and clastic heavy minerals and so on.

Bauxite definition names is not enough unity, this is related to resources from all countries and industrial demand. Name of various periods are inconsistent, but basically the same. In China it is generally believed: "bauxite refers to the aluminum content of ore is higher (40%), al-si ratio (A/S (2.5 or higher) is greater than 2.5, which is less than the numerical value is called clay or shale or aluminum bauxite rock". In China's proven reserves of bauxite, LvShiXing monohydrate bauxite accounts for about 98% of the country's total reserves.

Garnet abrasive, island structure is the use of aluminum (calcium) silicate minerals from the processing of ore. Garnet abrasive aka "waterjet sand" or "emery", garnet abrasive having a melting point higher than the major, acid-resistant, wear-resistant, high strength, chemical stability and other characteristics.

2014年2月18日星期二

2014年2月11日星期二

Fused quartz manufacturer details

Fused silica sand Which H&X pink fused alumina from the price and quality

Each company trading fused silica sand, will have a common point, that is the price of fused silica sand, fused silica sand price is the prime consideration customer choice, and our factory is located in the resource-rich quartz sand birthplace of Jiangsu Lianyungang, which is why I plant a big advantage in doing quality assurance while melting quartz sand prices in the peer also has a large advantage. The production of quartz sand, fused silica sand, silica powder, is signed by the National Building Materials Bureau for H&X silicon carbide micropowder products. With advanced processing equipment and production technology of quartz, relying on domestic resources, abundant high-quality quartz, following today's ever-changing market, according to market demand, developed a variety of high quality products.

Each company trading fused silica sand, will have a common point, that is the price of fused silica sand, fused silica sand price is the prime consideration customer choice, and our factory is located in the resource-rich quartz sand birthplace of Jiangsu Lianyungang, which is why I plant a big advantage in doing quality assurance while melting quartz sand prices in the peer also has a large advantage. The production of quartz sand, fused silica sand, silica powder, is signed by the National Building Materials Bureau for H&X silicon carbide micropowder products. With advanced processing equipment and production technology of quartz, relying on domestic resources, abundant high-quality quartz, following today's ever-changing market, according to market demand, developed a variety of high quality products.

2014年1月19日星期日

Widely used silicon carbide refractories

The main raw material used for the production of silicon carbide batts, laminectomy, brackets, sagger muffle boards, in addition to H&X silicon carbide grit with high strength, hardness and other inherent characteristics, but also with high load softening point, heat quickly, antioxidant , shrinkage deformation at high temperatures is not easy, and long service life. Regardless of the product (gas, coal, oil,electricity) which has a bend deformation can H&X Al2O3 powder at high temperatures, does not swell off the slag, fine features and strong thermal radiation, widely praised by users. Our factory uses advanced hydraulic vibration molding equipment, molding, unique formula, advanced technology, praised by users.

Alumina, the main raw material for the production of alumina wear-resistant ceramic lining brick, patch; wear-resistant ceramic pipe, elbow; wear-resistant ceramic lining, etc., are widely used in papermaking, power plants, chemical industry, metallurgy, mining equipment and other industries, after the majority of users use proven product quality, is the ideal replacement for other materials.

Alumina, the main raw material for the production of alumina wear-resistant ceramic lining brick, patch; wear-resistant ceramic pipe, elbow; wear-resistant ceramic lining, etc., are widely used in papermaking, power plants, chemical industry, metallurgy, mining equipment and other industries, after the majority of users use proven product quality, is the ideal replacement for other materials.

2013年12月20日星期五

Impact SM superplasticizer and zircon refractory castable

Abstract: SM superplasticizer on castable flow values and mechanical properties, as well as adding zircon aluminum powder for refractory castable material impact on the residual thermal shock flexural strength. The results showed that in the test range increases with SM castable flow amount increases, the volume density, reduced porosity, compressive strength, flexural strength increases; Zircon with increasing thermal shock 15 times the residual flexural strength increases first and then decreases.

Brown Corundum Industrial Technology> Chemical Industry> Portland Industrial> Industrial Refractories> Refractory Products> unshaped refractories> castable

Keywords SM superplasticizer zircon refractory castable

Brown Corundum Industrial Technology> Chemical Industry> Portland Industrial> Industrial Refractories> Refractory Products> unshaped refractories> castable

Keywords SM superplasticizer zircon refractory castable

Modulation of alumina cement refractory castable development

Abstract: The development of Sic Refractory containing fine particles are added to the agent alumina cement castable modulation. Agent is used to join aluminum thermal decomposition of ferrochrome from slag and high alumina screenings. Such castable studied the physical and mechanical properties and thermal properties.

Spinel is magnesium Alumina Oxides spinel mineral composition, because it contains magnesium, iron, zinc, manganese, etc. elements, which can be divided into many kinds, such as aluminum spinel, spinel iron, zinc spinel manganese spinel, chrome spinel. Because it contains different elements, different spinel can have different colors, such as magnesium spinel between red, blue, green, brown or colorless; zinc spinel was dark green; iron spinel black and so on. Spinel octahedral form or glassy hard particles and lumps. They appear in igneous, metamorphic and granitic pegmatite limestone. Some pretty transparent and color as spinel stones, some as magnetic iron. Using artificial methods already create over 200 varieties of spinel.

Spinel is magnesium Alumina Oxides spinel mineral composition, because it contains magnesium, iron, zinc, manganese, etc. elements, which can be divided into many kinds, such as aluminum spinel, spinel iron, zinc spinel manganese spinel, chrome spinel. Because it contains different elements, different spinel can have different colors, such as magnesium spinel between red, blue, green, brown or colorless; zinc spinel was dark green; iron spinel black and so on. Spinel octahedral form or glassy hard particles and lumps. They appear in igneous, metamorphic and granitic pegmatite limestone. Some pretty transparent and color as spinel stones, some as magnetic iron. Using artificial methods already create over 200 varieties of spinel.

Refractory one project won the national invention patents

Abstract: Steel Refractories Co., Ltd. "back seam aluminum powder reduction cell sidewall filled with gravity casting material" project by the State Intellectual Property Office patent licensing. This invention proposes a design specifically for aluminum cell, the cell is filled between the shell and the side wall slot gap using gravity casting material. The monolithic refractories can improve electrolytic tank and the side wall of life, not high-temperature firing, and can achieve rapid casting, Sic Refractory field is energy efficient environmentally friendly materials.

Category Industrial Technology> Chemical Industry> Portland Industrial> Industrial Refractories> Refractory Products> unshaped refractories

Keyword artesian invention patents monolithic refractories castable SIPO electrolytic cell design channel

Category Industrial Technology> Chemical Industry> Portland Industrial> Industrial Refractories> Refractory Products> unshaped refractories

Keyword artesian invention patents monolithic refractories castable SIPO electrolytic cell design channel

Effect of different binders for refractories description

Therefore, we must be selected for the workpiece material properties, in order to abrasive material good results. Binding agent must have the following properties: high strength, high heat resistance , a suitable hardness, small consumption of grinding , grinding efficiency , the surface roughness of the machined workpiece is better , fillers must be economical, but can be dissolved acid or base , to facilitate recycling . Superhard abrasive material is used as a binder resin material , phenolic resin is widely used , in addition to the epoxy resin , a novel phenol resin, a polyurethane resin, a polyimide resin, and bakelite powder. Brown Corundums can be classified according to the type : inorganic binder and organic binder . Inorganic binders include vitrified , metal bond , magnesite binding agent. Organic binder resin binders include rubber binder. Resin binder itself has good flexibility and polished , the formation of abrasive , still has a good self-sharpening , clogging, less trimming , and high grinding efficiency, low grinding temperature, surface grinding finish, so the wide range of applications . Combine to form a diamond abrasive resin bond diamond abrasive, often applied .

Impact of nanomaterials on refractories

Reduce the cost of production of clean steel mills continue to pursue each . Steelmaking Sic Refractory plays a key role in this regard , therefore , refractory facing greater challenges , in order to resist the harsh operating conditions , such as various types of high-speed steel casting , cold casting , etc., need to design a suitable refractory . Focus of this article is the key issue refractory products , such as increased erosion resistance Cypriot club head and submerged nozzle slag line , as well as to improve the high temperature strength of the product and so on . By introducing different proportions in the form of nano- oxide and non-oxide materials research special organic binding agent , developed the desired product. Through research, the final design of the casting process to match the low-cost products .

Discusses the specific requirements of calcium silicon refractory clay construction performance , sample tests conducted in accordance with the existing national technical standards, with a level of granularity and performance construction materials to give the agents studied. Ultimately concluded that a reasonable level of granularity is the oven with excellent access to basic construction performance with siliceous fireclay . You must add water-soluble organic and inorganic additives in combination , in order to make good fire clay construction performance .

Discusses the specific requirements of calcium silicon refractory clay construction performance , sample tests conducted in accordance with the existing national technical standards, with a level of granularity and performance construction materials to give the agents studied. Ultimately concluded that a reasonable level of granularity is the oven with excellent access to basic construction performance with siliceous fireclay . You must add water-soluble organic and inorganic additives in combination , in order to make good fire clay construction performance .

2013年12月19日星期四

The comparison of two kinds of rare earths

1, re - Alumina Oxides alloy in the middle

Single rare earth metal chemical is high, easy oxidation burning loss during smelting, storage and transportation is not very convenient, cost is high, and high melting point, density, not easy to add to the aluminum. In most cases, therefore, are among the prefabrication of the rare earth - aluminum alloy, not only can reduce the oxidation burning loss, reduce the cost, and convenient transport. Join, simple and safe operation, and components are easy to control, available composition is stable, reliable quality of the alloy.

2, rare earth application in high purity aluminum powder capacitor

Containing rare earth high purity aluminum special aluminum foil, is an ideal new material in the low production of electrolytic capacitors. Some capacitor factory that, after adding trace rare earth in high purity aluminum, can dramatically increase the corrosion of aluminum electrolytic capacitor anode aluminum foil coefficient K, and the strength, capacitance is increased significantly. Made significantly smaller capacitor, the material has been batch used in some of the capacitor, and obtained a certain effect. But the effect mechanism of rare earth in them, have different opinions, is carrying out in-depth research.

Single rare earth metal chemical is high, easy oxidation burning loss during smelting, storage and transportation is not very convenient, cost is high, and high melting point, density, not easy to add to the aluminum. In most cases, therefore, are among the prefabrication of the rare earth - aluminum alloy, not only can reduce the oxidation burning loss, reduce the cost, and convenient transport. Join, simple and safe operation, and components are easy to control, available composition is stable, reliable quality of the alloy.

2, rare earth application in high purity aluminum powder capacitor

Containing rare earth high purity aluminum special aluminum foil, is an ideal new material in the low production of electrolytic capacitors. Some capacitor factory that, after adding trace rare earth in high purity aluminum, can dramatically increase the corrosion of aluminum electrolytic capacitor anode aluminum foil coefficient K, and the strength, capacitance is increased significantly. Made significantly smaller capacitor, the material has been batch used in some of the capacitor, and obtained a certain effect. But the effect mechanism of rare earth in them, have different opinions, is carrying out in-depth research.

Rare earth unique explanation

Rare earth and many of the unique physical and chemical properties to develop the alloy containing rare earth materials. Rare earth is not only a large number of used in military industry, silicon carbide powders, light industry, handicraft industry and transportation industry, also widely used as building materials, appliances and sporting goods such as family life.

The application of rare earth in conductive aluminum alloy, is now widely used in China, high technology is relatively mature, industrial value and economic benefit is good one area. High conductivity of rare earth alloy, usually refers to the pure aluminum, aluminum powder - magnesium - department of silicon and aluminum - magnesium alloy adding rare earth alloy, and aluminum zirconium - yttrium alloys. Mainly used in the manufacture of overhead transmission line, cable, sliding wire, wire core, general wiring, special purpose of fine lines and fine lines, aluminum wire. Its development soon, has risen from 315 V to 500 V on the high tension line, area from dozens to hundreds of was, was by the development of wire and cable and then to the conductive bus. They are at the new products, has become China's conductive aluminum alloy with high strength, large carrying capacity, long service life, wear resistance and easy processing characteristics. At present, more than 20 domestic provinces and cities, factory production of rare earth alloy wire

The application of rare earth in conductive aluminum alloy, is now widely used in China, high technology is relatively mature, industrial value and economic benefit is good one area. High conductivity of rare earth alloy, usually refers to the pure aluminum, aluminum powder - magnesium - department of silicon and aluminum - magnesium alloy adding rare earth alloy, and aluminum zirconium - yttrium alloys. Mainly used in the manufacture of overhead transmission line, cable, sliding wire, wire core, general wiring, special purpose of fine lines and fine lines, aluminum wire. Its development soon, has risen from 315 V to 500 V on the high tension line, area from dozens to hundreds of was, was by the development of wire and cable and then to the conductive bus. They are at the new products, has become China's conductive aluminum alloy with high strength, large carrying capacity, long service life, wear resistance and easy processing characteristics. At present, more than 20 domestic provinces and cities, factory production of rare earth alloy wire

Rare earth removal of impurities and on the influence of the inclusions

Distribution in aluminum and its alloy matrix and grain boundary compounds for all kinds of intermetallic compound and the oxide and aluminum oxide. The composition, morphology, distribution and quantity of these compounds on the performance of the aluminum and its alloys, especially the plastic processing and performance has a significant influence. Inclusion of aluminum powder and its alloy owner if Al2O3 etc. Nonmetal inclusion, its existence not only reduce the processing performance and mechanical properties of alloy, and worsen the casting performance. When pure aluminium (as-cast, variable form) after adding 0.2% of rare earth, the distribution of the original intracrystalline bulky blocks disappear, spherical rare earth phase formation, grain boundary strips and fragmental compounds decreased significantly, the point chain compound forming, plastic good uniform organization. And found that after adding 0.2% rare earth alloy, the original is distributed in the intracrystalline glomeration of rough patches, and in the uniform distribution of globular phase is formed on the substrate, while eliminating the boundary brittle fragmental and strip compounds, forming small point chain distribution of plastic compounds, and lined up along the deformation direction. To join before and after the rare earth Alumina Oxide and its alloy matrix, the grain boundary in the compound, intracrystalline bulky compounds and globular compounds such as phase composition were determined. Contrast found that after joining the rare earth, which makes the impurity in the aluminum and its alloys, such as iron and other elements, to high rare-earth poly globular phase, so that the final solidification grain boundary of impurity element is greatly reduced, purify grain boundary, the grain boundary in high-speed rail brittle phase reduction, grain boundary strength increased, the plastic improvement; And grain boundary distribution point chain compounds as low iron, the composition of rare earth phase, is close to the aluminum substrate of plastic compounds, particularly in the rare earth alloy spherical phases partial quantity is relatively pure aluminium cuhk, so its distribution in aluminum alloy grain boundary minimal, so the boundary of aluminum alloy is more thin, more pure than pure aluminium.

The role of rare earth in aluminum and its alloy

Rare earth elements is very lively, extremely easily with gas (e.g. hydrogen), non-metallic (such as sulfur) and generate the corresponding stable compound metal effect. The atomic radius of rare earth calcium silicons is less than common metal, such as lead, magnesium, etc., in the solid solubility of these metals is extremely low, almost can't form a solid solution. In the rare earth elements added to the aluminum alloy can have the effect of micro alloying; In addition, it with gas such as hydrogen and many non-metallic strong affinity, can generate high melting point compounds, so it has certain than hydrogen, refining, purification effect; At the same time, the rare earth elements strong chemical activity, it can be selectively on has formed the grain interface adsorption, hinder the growth of the grain, with the result that grain refinement and qualitative change.

metamorphism

Modification Brown Corundums is to point to add a small amount of in metal and alloy or trace of inoculant, to change the alloy crystallization conditions, make its organization and performance improvement process. Metamorphic agent is also called the grain refining agent and nucleating agent. Typically, rare earth atomic radius. Because of rare earth elements is lively, it melt to fill easily in the liquid aluminum alloy phase surface defects, and reduces the surface tension of the old and the new two phase interface, make the crystal nucleus growth rate increased. At the same time it also can between grain and alloy liquid in the formation of surface active membrane, prevent generating of grain growth, thus refine the organization of the alloy. In addition, as an exotic crystal nucleus, aluminum and rare earth compounds in metal crystal formation, due to the large increase in number of crystal nucleus and thus refine the organization of the alloy. Rare earths in al-si alloy is mainly the metamorphism, make needle, lamellar eutectic silicon spherulitic, make less of the scale of the primary silicon. The stale ability is different, different rare earth La and Eu has strong metamorphism, and the mixture of rare earth and Ce only moderate ability of metamorphism. Lanthanide metamorphic ability has a close relationship with atomic radius, as the atomic radius from La to Er of 0.187 nm 0.175 nm, the metamorphic capacity decreases. All in atomic radius is less than 0.18 nm, metamorphism is reduced to the point of no practical significance. Different metamorphic ability of rare earth elements available critical cooling rate of deterioration (Vc), Vc is smaller, the bad effects, the more obvious; When V is smaller than that of Vc, any concentration of rare earth elements can cause alloy, this is one of the main difference between rare earth and other metamorphic agent.

metamorphism

Modification Brown Corundums is to point to add a small amount of in metal and alloy or trace of inoculant, to change the alloy crystallization conditions, make its organization and performance improvement process. Metamorphic agent is also called the grain refining agent and nucleating agent. Typically, rare earth atomic radius. Because of rare earth elements is lively, it melt to fill easily in the liquid aluminum alloy phase surface defects, and reduces the surface tension of the old and the new two phase interface, make the crystal nucleus growth rate increased. At the same time it also can between grain and alloy liquid in the formation of surface active membrane, prevent generating of grain growth, thus refine the organization of the alloy. In addition, as an exotic crystal nucleus, aluminum and rare earth compounds in metal crystal formation, due to the large increase in number of crystal nucleus and thus refine the organization of the alloy. Rare earths in al-si alloy is mainly the metamorphism, make needle, lamellar eutectic silicon spherulitic, make less of the scale of the primary silicon. The stale ability is different, different rare earth La and Eu has strong metamorphism, and the mixture of rare earth and Ce only moderate ability of metamorphism. Lanthanide metamorphic ability has a close relationship with atomic radius, as the atomic radius from La to Er of 0.187 nm 0.175 nm, the metamorphic capacity decreases. All in atomic radius is less than 0.18 nm, metamorphism is reduced to the point of no practical significance. Different metamorphic ability of rare earth elements available critical cooling rate of deterioration (Vc), Vc is smaller, the bad effects, the more obvious; When V is smaller than that of Vc, any concentration of rare earth elements can cause alloy, this is one of the main difference between rare earth and other metamorphic agent.

Aluminum oxide cleaning liquid

The used motor shell is very difficult to clean

Oil pollution situation is more complex

May also with dirt and dust

Going to the Alumina Oxides layer is not black cannot use hydrochloric acid, can only use ultrasonic cleaner and cleaner

I come into contact with a similar situation

For your reference

1, automatic ultrasonic cleaning line

High pressure spraying and aluminum cleaner (removal of workpiece surface soil, and heavy dirt)

Ultrasonic aluminum cleaner (thoroughly remove the workpiece surface oil pollution)

Ultrasonic aluminum powder oxide cleaner (removal of oxide layer)

Rinse (if there is oil plus an ultrasonic aluminum cleaner process)

Rinse and drying

2, manual cleaning and ultrasonic oxidation layer

In an aluminum cleaner first

Artificial scrub (using aluminum cleaner, remove dust dirt oil dirties, instead of high pressure spray)

Ultrasonic cleaner to remove oxide aluminum oxide layer

Rinse (if there is oil plus a scrub)

Oil pollution situation is more complex

May also with dirt and dust

Going to the Alumina Oxides layer is not black cannot use hydrochloric acid, can only use ultrasonic cleaner and cleaner

I come into contact with a similar situation

For your reference

1, automatic ultrasonic cleaning line

High pressure spraying and aluminum cleaner (removal of workpiece surface soil, and heavy dirt)

Ultrasonic aluminum cleaner (thoroughly remove the workpiece surface oil pollution)

Ultrasonic aluminum powder oxide cleaner (removal of oxide layer)

Rinse (if there is oil plus an ultrasonic aluminum cleaner process)

Rinse and drying

2, manual cleaning and ultrasonic oxidation layer

In an aluminum cleaner first

Artificial scrub (using aluminum cleaner, remove dust dirt oil dirties, instead of high pressure spray)

Ultrasonic cleaner to remove oxide aluminum oxide layer

Rinse (if there is oil plus a scrub)

2013年10月24日星期四

How much is the density of corundum?

Density is divided into two kinds of Brown Corundum is called, one corundum bulk density, particle density, the second is Brown Corundums.

Bulk density of 1.53 ~ 1.99g/cm3, abrasives and abrasive particle bulk density, particle size composition, species, particle shape and other factors are related, in general, coarse-grained than fine-grained abrasive abrasive bulk density, particle size of the abrasive mix Bulk density is greater than a single particle density.

Particle density of 3.95 ~ 4.0/cm3, the silicon carbide abrasive particle density refers to the unit volume (excluding the volume of open porosity) contained within the abrasive mass

Bulk density of 1.53 ~ 1.99g/cm3, abrasives and abrasive particle bulk density, particle size composition, species, particle shape and other factors are related, in general, coarse-grained than fine-grained abrasive abrasive bulk density, particle size of the abrasive mix Bulk density is greater than a single particle density.

Particle density of 3.95 ~ 4.0/cm3, the silicon carbide abrasive particle density refers to the unit volume (excluding the volume of open porosity) contained within the abrasive mass

2013年9月9日星期一

Common types of abrasive

Need to use the mold with abrasive, abrasive and share with everyone today, the main species, which mainly include mainly corundum, white corundum, silicon carbide and green silicon carbide.

Corundum high toughness, suitable for grinding carbon steel, alloy steel, malleable iron and hard bronze high tensile strength of the material. Corundum has a higher hardness than corundum, cutting performance is better, for hardened steel, high carbon steel, high speed tool materials such as grinding processes.

Black silicon carbide, high hardness, brittle and sharp, suitable for grinding, cutting, low tensile strength of the material, such as: cast iron, glass, ceramics, stone, refractory material and so on.

Darker green silicon carbide high purity silicon silicide. Suitable for grinding carbide, optical glass, precious stones, agate and other hard and brittle materials.

Granularity:

The choice of abrasive particle size depends on the surface of the workpiece machining accuracy and productivity requirements. Coarse-grained and medium-grained abrasive for roughing and semi-finishing, and fine-grained abrasive, it applies to finishing and super finishing. Physical and mechanical properties are grinding department also factors that determine particle size, low hardness, ductility and toughness of the material is appropriate to coarse-grained abrasive machining, high hardness brittle materials appropriate to fine-grained abrasive.

Organization:

Organization refers to the abrasive grinding composition of the abrasive, bond and porosity volume ratio between the three. Less abrasive, large porosity called loose tissue, otherwise tightly organized.

Tightly organized abrasive, should be used for grinding, profile grinding and processing remain small while the surface finish of the workpiece.

Medium organizations are widely used in the general allowance abrasive grinding work piece.

Loose abrasive for flat organization, such as the inner circle of a large contact surface of the grinding and grinding expansion sensitive soft material of the workpiece and the workpiece.

Hardness:

Abrasive abrasive surface is fixed to the strength of the binding agent. Or under external force, the degree of difficulty shedding, known abrasive hardness.

Corundum high toughness, suitable for grinding carbon steel, alloy steel, malleable iron and hard bronze high tensile strength of the material. Corundum has a higher hardness than corundum, cutting performance is better, for hardened steel, high carbon steel, high speed tool materials such as grinding processes.

Black silicon carbide, high hardness, brittle and sharp, suitable for grinding, cutting, low tensile strength of the material, such as: cast iron, glass, ceramics, stone, refractory material and so on.

Darker green silicon carbide high purity silicon silicide. Suitable for grinding carbide, optical glass, precious stones, agate and other hard and brittle materials.

Granularity:

The choice of abrasive particle size depends on the surface of the workpiece machining accuracy and productivity requirements. Coarse-grained and medium-grained abrasive for roughing and semi-finishing, and fine-grained abrasive, it applies to finishing and super finishing. Physical and mechanical properties are grinding department also factors that determine particle size, low hardness, ductility and toughness of the material is appropriate to coarse-grained abrasive machining, high hardness brittle materials appropriate to fine-grained abrasive.

Organization:

Organization refers to the abrasive grinding composition of the abrasive, bond and porosity volume ratio between the three. Less abrasive, large porosity called loose tissue, otherwise tightly organized.

Tightly organized abrasive, should be used for grinding, profile grinding and processing remain small while the surface finish of the workpiece.

Medium organizations are widely used in the general allowance abrasive grinding work piece.

Loose abrasive for flat organization, such as the inner circle of a large contact surface of the grinding and grinding expansion sensitive soft material of the workpiece and the workpiece.

Hardness:

Abrasive abrasive surface is fixed to the strength of the binding agent. Or under external force, the degree of difficulty shedding, known abrasive hardness.

2013年8月17日星期六

Classification and the use of a variety of abrasive range

Abrasive

grinding material is used, the general classification is now common

abrasives, superhard abrasive types; ordinary abrasive including corundum (corundum, corundum, etc.), and its main chemical composition

Al2O3 (aluminum oxide) , silicon carbide (black silicon carbide, green silicon carbide), and its main chemical components of SiC (silicon carbide). They

are corundum hardness, microhardness 2000-2200 kgf / mm 2; corundum,

microhardness 2200-2300 kgf / mm 2; black silicon carbide, microhardness

3100-3300 kgf / mm 2 ;

green silicon carbide, microhardness 3200-3400 kgf / mm 2; grain size

from 4 # - powder W0.5 (or finer), the hardness in the order that we can

sort out the processing of granite is green silicon carbide, black

carbonized silicon processing marble is corundum (soft), black, green silicon carbide (hard).The

cost from the material in order to see the green silicon carbide, black silicon carbide, corundum, abrasives can be made around these,

inorganic abrasive tool including magnesite, ceramics, etc.; organic

grinding tools, including phenolic, unsaturated

resins, and epoxy, etc. (This also includes emery cloth sandpaper),

which constitute the common abrasive grinding tools, grinding tools.Superabrasive

diamond abrasive belongs, and its processing history is a relatively

long, but as more use is the last three decades a large number of

industrial production, and its hardness 8000-10000 kgf / mm 2; hardness

is the highest ,

processed materials are micro-cutting mechanism, so it is the preferred

cutting tool, in recent years, there is a massive increase in the yield

and reduction of industrial costs, high processing efficiency, (which

is 5 times more than normal), the processing effect (may demanding material for polishing), and thus, it is a widely used.Diamond

grinding tools are metal, resin, ceramics, etc. This is the type of

binding agent according to the classification, metal grinding

instruments mainly include iron-based, copper-based, these types of

cobalt, it determine

the different types of materials processing costs, as grinding tools,

from the most coarse particle size (20 #), often to the fine grain size

up to 400 # for use; which is characterized by long life, but the cost

will be higher.Resin

grinding tools, due to the production costs are relatively low, the

application should be relatively more, it is now also used for rough

grinding to polishing, grinding and polishing in the fine-grained

aspects is its greatest advantage; ceramic diamond grinding tools are

recent was

the fastest growing tool, its processing performance in metalworking

take long, to avoid resin processing short, is technically a good

advantage, but because of cost reasons, have not seen used in stone

renovation.

订阅:

博文 (Atom)